HPL Manufacturers: What Does CTI Deliver?

Fortunately, contract manufacturers like CTI are able to deliver HPL to clients in a timely manner, accommodating your specific demands. For decades, CTI has delivered laminating services. With our level of expertise and experience, we ensure that you get exactly what you require. CTI takes a modular approach to manufacturing, which makes it easier for us to create products that are tailor made for our clients. Nonetheless, you may want to educate yourself further about HPL manufacturing before committing to a service provider. With that being said, let’s dive in to the world of HPL manufacturing. The more you know, the easier it will be for you to discuss your order with CTI.

How is High Pressure Laminate Made?

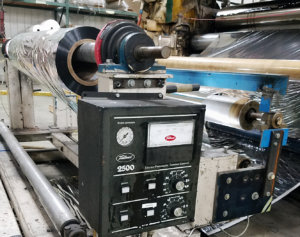

The basic process behind manufacturing HPL (which can vary somewhat depending on your specific order and the grade needed) involves kraft paper. First, we saturate multiple layers of paper in phenolic resin. After this, a layer of décor paper is pressed on top of the saturated pieces. Heat and pressure are simultaneously applied to the stacked papers, typically under forces that amount to more than 1,000 PSI.

Notably, the HPL manufacturing process actually turns the resin into plastic. This is because phenolic and melamine resins are thermoset. Essentially, what were previously multiple layers of paper become one rigid laminate sheet. The thermo-setting results in a product that is stronger than alternatives, and you can use it in both horizontal and vertical applications. Therefore, they work on countertops and cabinets alike, as well as flooring and wall treatments.

Due to its durability, you can apply HPL in various different settings. From kitchens to hotels, or even corporate office buildings, you can easily find HPL. Furthermore, HPL manufacturers have advanced their techniques to the point that they can produce HPL that looks very similar to more expensive products. HPL can even mimic the appearance of high-end stone surfaces.

What Are the Different HPL Grades?

As previously mentioned, there are different grades of HPL. Experienced HPL manufacturers can often offer multiple or even all grades. Different HPL grades typically serve different purposes. They include:

- Backer HPL. This laminate performs without the decorative face commonly associated with traditional HPL. This in itself comes in two different forms. One is standard, which is a bit thinner than the typical HPL. The other is regrind, which is actually reclaimed HPL. Manufacturers sand off the decorative surface, effectively creating a fresh surface.

- Special product HPL. In contrast, special product HPL is meant for more individualized purposes. You could consider it a more customized product. Typically, cabinet liners will fall into this category, as well as fire-rated, high-wear, electrostatic dissipative and chemical resistant laminates.

- General purpose HPL. As opposed to special product HPL, general purpose HPL is the all-encompassing HPL most commonly ordered. Utilized for horizontal or vertical applications, it is usually produced with .028 inch to .048 inch thickness levels, and is broadly used.

- Postforming HPL. Finally, this laminate typically forms around curved surfaces. We accomplish this through high pressure applications, and it typically won’t exceed more than .038 inches in thickness.

Who Can Provide High Pressure Laminating Services?

Whether you’re sourcing HPL for your own project or for a client, you’ll want to ensure that you’re working with experienced HPL manufacturers. Fortunately, CTI has plenty of experience in not only HPL manufacturing, but a wide variety of other laminating services. CTI is the industry leader in laminating services, and with good reason.

One of the main reasons why clients so often turn to us as opposed to competitors is that we make it easy for them, while at the same time offering flexibility. You can be as removed or as involved in the process as you wish. We approach HPL manufacturing with our proven step-by-step system. Through this system, we first work with you in an initial consultation to establish whether or not we should work together. From that point, we can move on to research and development, devising the best possible strategy for your project. We conduct lab testing and deliver samples before we produce an initial pilot run. Only after we assure your satisfaction with the initial pilot run, we deliver the final product.

HPL is not a simple product, and the reality is that you could risk losing both time and money if you don’t work with proven HPL manufacturers. You need to work with a producer that has experience and knowledge regarding different grades, as well as the specific processes necessary to deliver the grade you require. Now that you know that CTI can deliver high quality HPL, why not schedule an initial consultation? Give us a call at 419-924-5566 or reach out to us here. We’re ready to deliver exactly what you need!

- << < Previous Post

- 1

- 2

- ...

- 81

- ...

- 250

- 251 Next Post > >>